EROWA fixture types

EROWA fixture types

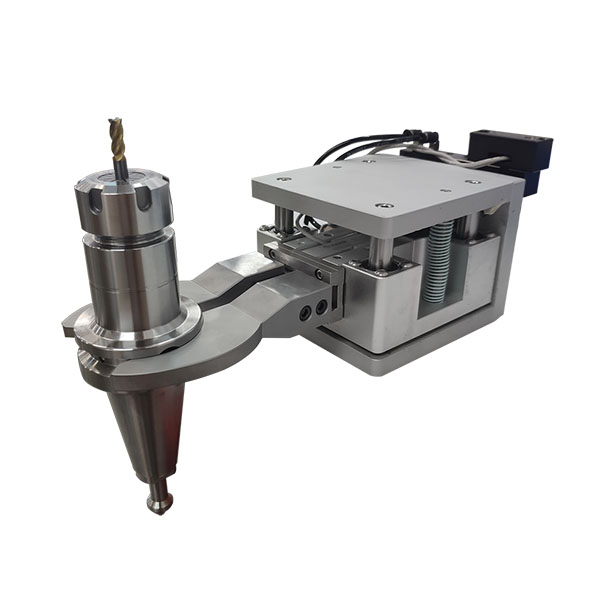

Horizontal type. Vertical type. Push-pull type. Latch type. Welding group vertical type. F-type clamp.

EROWA tooling fixture application range:

It is widely used in manufacturing electronic parts and equipment and the sheet metal assembly of the frame feet of automobiles and motorcycles.

Production of sports equipment, aircraft assembly, qualitative PU molding, and fixed clamping for parts processing and assembly in toy and handicraft processing plants.

Prevent the deformation of plastic injection products, planing and milling of related parts in wooden product processing plants, etc.

When the connection of industrial pipelines such as chemical pharmacy, food, etc., the opening and closing of the tank cover, and various mass production involve the processing of fixed objects, other kinds of fixed clamping can be completed, or work occasions can use machine tool fixtures.

A fixture is a device used to clamp a workpiece on a machine tool called the "hand" of the machine tool. The use of machine tool fixtures can ensure the machining accuracy of the workpiece, reduce auxiliary person-hours, significantly improve production efficiency, and expand the scope of machine tools used to achieve "one machine with multiple functions." It is used in metal cutting processing and inspection, assembly, welding parts, production line manufacturing, and other processes.

EROWA fixture is only a supporting industry, not a pillar industry, but various fixtures must be used in the machining process. Fixtures are necessary to process equipment and have vast market potential.

Central tightening force of EROWA tooling fixture:

Central tightening force refers to the pressing force of the indenter against the workpiece when the clamp is in the locked position without mechanical deformation. This pressing force is generated when the indenter is adjusted on the arm to a position close to the mounting seat. The pressure of the indenter on the workpiece is not fixed, and it changes with the different positions of the indenter on the arm. When the mounting seat is separated, the clamping force decreases.

Features of EROWA tooling fixture:

1. Simple structure and easy installation.

2. Fast loading and unloading of clamped workpieces and convenient operation.

3. All parts are treated with electroplating and anti-rust, and the surface is smooth and beautiful.

4. For heavy-duty fixtures, the essential parts are heat-treated to have higher strength and wear resistance.

The development prospects of EROWA tooling fixtures:

Unleash all the potential of your machine tool.

To make your workshop more competitive, you need to remove inefficiencies in your workflow. Manual installation settings on the machine tool are the weak link. Making up for the wasted time is the top priority. Learn more about the industry news about nozzles suppliers, and learn about Cycospray from now on to get professional advice!

评论

发表评论