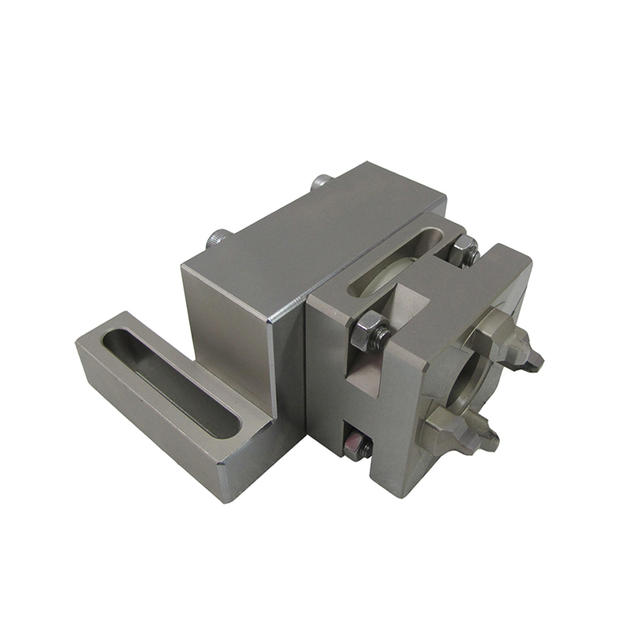

EROWA fixture production

The production of erowa fixtures is a comprehensive science. We need to clarify the design tasks, analyze the drawings of the parts, master the machining process regulations of the workpieces, understand the functions, shapes, structural characteristics, materials and technical requirements of the workpieces; the processed surfaces, requirements, Data on margins, positioning datums, clamping surfaces, etc.

Practice has proved that only by constantly summing up experience, carefully collecting design information, mastering design criteria, rationally drawing out the structure plan of the fixture, correctly arranging the manufacturing process and assembly process, it is possible to produce a reasonable structure even on the basis of limited conditions. Reliable positioning, economical and practical fixture. In addition, the design and application of the fixture greatly facilitate the processing of circular or shaft parts, with simple structure and convenient operation, which can reduce costs, improve work efficiency, and ensure quality, and has good promotion and application value.

EROWA tooling fixture

When the groove width of the processed part is less than or equal to 1mm, it is difficult to process with ordinary mechanical equipment, because the smaller the cutting tool, the greater the processing difficulty, and even the processing cannot be performed. In this case, it is necessary to use special processing electrical appliances. Spark cutting or other electrical processing equipment processing methods can effectively solve the processing of narrow groove parts. It has always been regarded as one of the more difficult processes for processing. Because the idea of developing auxiliary fixtures has been developed, and the use effect is good, it solves the problem of online The technical difficulties of cutting machine tools to process batch products.

Not long ago, a company commissioned us to process a batch of ring products. In the processing and production of this part, a useful attempt was made to process narrow grooves with a groove width of only 0.2mm and evenly distributed around the circumference, and achieved good results. As a result, the basic dimensions of the part are: φ48MM×75MM, and the material is 45 steel.

评论

发表评论