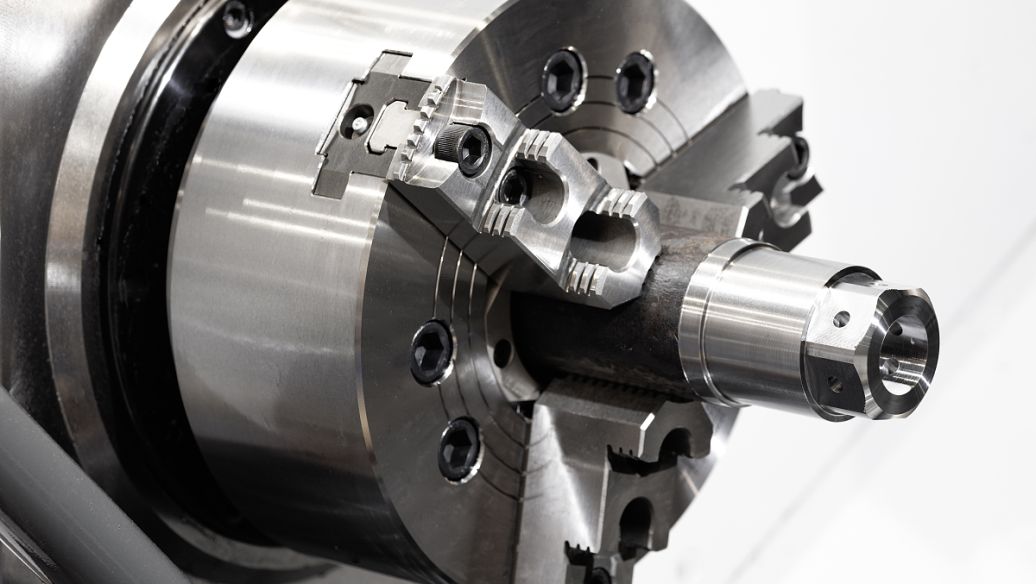

Use and maintenance of hydraulic chuck

Do you know about hydraulic chucks? Today, the Pofi hydraulic chuck manufacturer will introduce the common faults of hydraulic chucks and the daily maintenance of hydraulic chucks.

Use and maintenance of hydraulic chuck

During the use of the hydraulic chuck, we may encounter some use failures. Don't panic at this time. After years of use experience, we have sorted out the corresponding solutions, which are roughly divided into the following points:

1. The chuck does not clamp the workpiece tightly. The main reason is that the jaw stroke is not enough, the clamping force of the chuck is insufficient, the arc diameter of the soft jaw is different from the diameter of the workpiece, the cutting force is too large, the sliding surface of the sliding seat is lubricated and the speed is insufficient. If it is too high, the solution is to re-clamp the workpiece so that the jaws are at the mid-point of the stroke when clamping, check whether the set oil pressure meets the requirements, and re-arrange the soft jaws to make the clamping arc diameter consistent with the diameter of the workpiece.

2. The lubricating oil is insufficient and the speed is too high. The solution is to re-clamp the workpiece so that the jaws are at the mid-point of the stroke when clamping, check whether the set oil pressure meets the requirements, and re-arrange the soft jaws to make the clamping arc diameter and If the diameter of the workpiece is the same, readjust the cutting parameters, re-lubricate each part and run it several times, reduce the speed to within the standard range, etc.

3. Poor accuracy, mainly due to excessive runout of the outer circle of the chuck, poor contact between the sliding seat or the comb tooth surface of the chuck, the super high height of the soft jaws, resulting in clamping deformation, excessive clamping force, deformation of the workpiece, and no drinking Hard claws mixed. The solution needs to be re-installed, correct the outer circle of the chuck and the end face beating. Remove the jaws to clean and lock the screw chuck. Common faults of hydraulic chucks are re-equipped with soft jaws and pay attention to the position of the forming ring, the size of the oil pressure and the clamping The surface roughness of the arc.

When we use the product, we must also carry out certain maintenance on the product, which is to improve the performance of the product to a certain extent.

Most of the machine tools rely on lubrication systems, because many machine tools are shared by hydraulic and lubrication systems, so it is necessary to consider meeting the requirements of each lubrication point for lubrication while ensuring the normal operation of the hydraulic system.

Under the premise of considering the operating cost, the oil with high viscosity index, good anti-wear and anti-oxidation properties should be selected as much as possible. Therefore, whether it is automatic processing, semi-automatic processing, traditional lathe refitting automation, special-purpose unit and other applications, hydraulic chucks are a good choice for customers.

评论

发表评论