POFI Fixture Enable Your Business To Stay Competitive

POFI focused our research on EDM clamping system tools, just in order to design tools to suit more working conditions and improve effiencients. With 17 years in this field, POFI get expericnce in techinic, customer serivce, management . We continually improve the efficiency of our energy use in our production processes. POFI supply the market EDM tools to imporive the efficiency of our customer's use of existing resources.

A: electrode automation series, Installed on CNC, EDM machine tools, 3D inspection platform, mainly used for lectrode processing electrical discharge processing, rapid positioning andeplacement.

B: MTS series, Installed on a CNC machining center, MTS series fixtures are more widely used than electrode automation fixtures. Multi-functional pallets can process large molds (800mm-1000mm) and can be equipped with vise and chuck on the panel

C: UPC chuck series,Installed in CNC 3dimensional inspection. Suitable for processing products within 400mm

D: robot parts, It is installed on the robot arm, and the workpiece can be quickly grasped by electronic chip detection and positioning.

Much experience always show that to find a solution to mini reduce machine downtime are more significantly than chasing seconds in the actual machining process. POFI edm tools, have the same interface, which can realize the flexible transformation from one processing to another, and from one lathe to another lathe, from EDM machine to CNC machine. This lets you preset away from the machine and then set up the machine with minimum idle time, quickly and precisely.

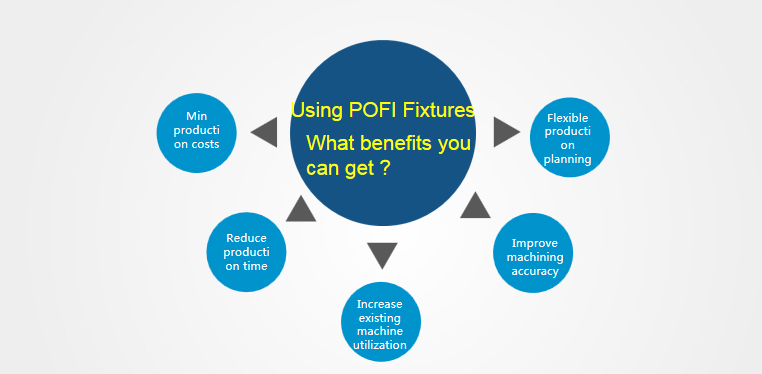

Using POFI Fixture system you can get:.

Min production cost, Min human error, Best production management .Flexible production plans High production quality Highest productivity

评论

发表评论