Attention points when using frock clamp

Attention points when using frock clamp

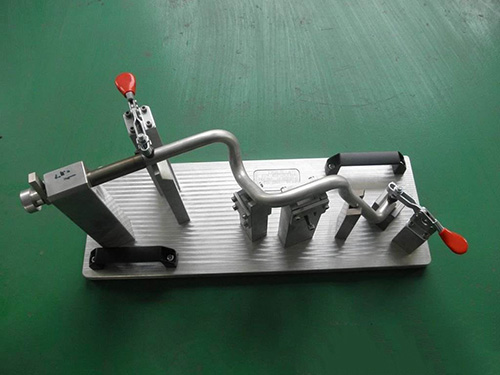

We will use a large number of production equipment such as welding frock clamp in industrial production and life, and fixtures are one of the common frock clamps composed of multiple work modules, and the modules can be based on the actual workpiece It can be adjusted according to the requirements, so that the whole tool system can realize the combination of two-dimensional and three-dimensional space. Below we will introduce the components of each series in detail.

In order to adapt to workpieces with different dimensions, the flexible modular fixture system is divided into 28 series and 16 series in welding production.

The components of each series can be divided into 8 categories according to their purpose:

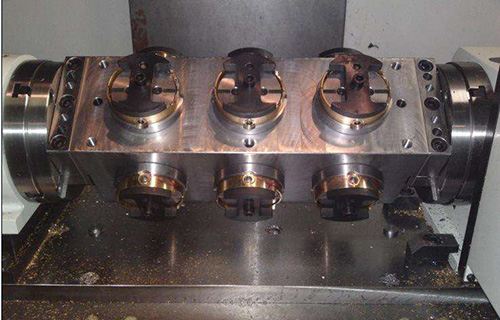

①Basic parts: such as square, rectangular, round foundation plates, etc., used as fixture tooling tables. The five working surfaces of the workbench have holes with grid marks of 100mm×100mm (D28 series) or 50mm×50mm (D16 series).

The plane, parallel, and vertical tolerance accuracy of the five surfaces and the position accuracy of holes and holes are all very high, ensuring that the positioning on the table and the combination between the table and other modules have sufficient accuracy requirements. The size of the base table can be selected arbitrarily from 1000mm×1000mm to 4000mm×2000mm, and special sizes can be customized. If the precision requirements of the combination of the table and the table are very high, you can use the guide rail to connect them.

②Supporting parts: including U-shaped square box, L-shaped square box, supporting angle iron, angle connecting block, angle device, frame support seat, etc.; used for height positioning or platform expansion and positioning or pressing of other accessories, yes In order to ensure that the workpiece meets a certain height requirement during the processing process, the components that position the support on the platform, such as gaskets, backing plates, support plates, support blocks, and extension plates, are mainly used as supports of different heights.

③Positioning parts: including positioning squares, flat squares, flat squares, V-shaped positioning parts, out-of-center circle stop, used to accurately adjust the positioning position or height, in order to ensure that the workpiece meets certain dimensional accuracy requirements during processing, and will Components for precise positioning of the workpiece; used to determine the relative position between the component and the component, and between the component and the workpiece.

④Adjustment parts: including: adjusting shims for height-adjusting devices; use: components for adjusting the gap between the component and the workpiece.

⑤Pressing parts: including: 90>deg; screw compactor, horizontal spiral compactor, 45>deg; spiral compactor, vertical pressing type quick fixture, horizontal push type quick fixture; purpose: to ensure that the workpiece is in the process of processing It is a component that is not displaced, but presses the workpiece on the platform or foundation component.

⑥Locking parts: including: quick lock pin, countersunk quick lock pin, countersunk lock pin, handle quick lock pin, positioning pin, connecting lock magnetic pin, inner hexagon lock pin, outer hexagon lock pin , Magnetic pin; Purpose: It is a component to ensure the positioning and locking between components.

⑦Composite parts: including: 90 degree clamping corner sleeve, 45 degree clamping corner sleeve, parallel clamping corner sleeve, vertical clamping corner sleeve, standard support leg, universal wheel support leg with brake, fixed support Legs, frame structure type support seat, hydraulic lifting type support seat, support rail; purpose: It is a component that acts on the connection or support between the component and other parts.

⑧Other parts: including: stop ring, grounding device, screw clamp, clamp pipe, lifting ring, cross groove pressure pad, two-point clamp bridge, three-point clamp bridge, multi-purpose support template, platform protection plate, tools Trolley; Purpose: It is a supporting accessory component for the assembly of tooling components.

⑨Assembly tools: including hex wrench, oil stone, magnetic forceps and other assembly tools.

评论

发表评论