The key problem of jig & fixture in machining

The key problem of jig & fixture in machining

Good jig & fixture can effectively ensure the efficiency of production and product quality, and improve the economic benefits of the enterprise. This article analyzes some key issues in the machining of jig & fixture for reference only.

Brief description of jig & fixture

The so-called tooling refers to process equipment, which refers to the general term for various tools used in the manufacturing process of industrial production. Tooling is divided into professional tooling, general tooling and standard tooling.

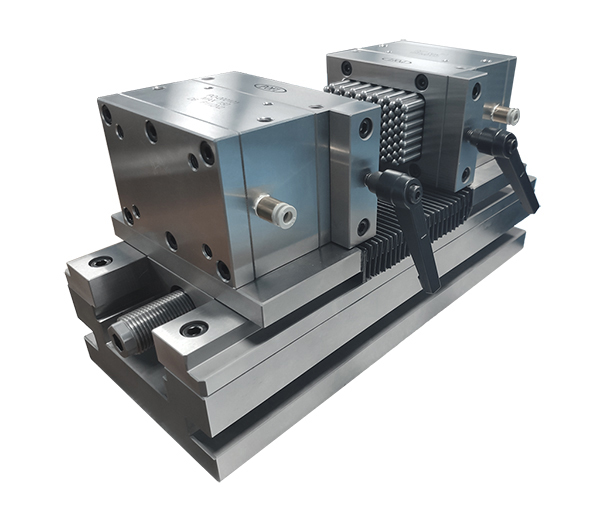

The so-called fixture, literally analysis, refers to the relevant device used to clamp the workpiece or guide the tool. Therefore, the jig & fixture is used to quickly tighten and fix the workpiece during industrial production and processing, so that the machine tool, cutting tool and workpiece can maintain the correct relative position.

Explained in a broad sense, in any process in the technological process of our factory, a device that can be used to make the installation of workpieces more convenient and safer, we can call it a "fixture." There are many types of jig & fixture, of which machine jig & fixtures are the most common, and we usually call them fixtures for short.

The necessity of jig & fixtures

The jig & fixture can ensure the processing accuracy of the production workpiece to a certain extent, and can stabilize the quality of the product. The application of jigs and fixtures plays a very important role in expanding the process range of machine tools and improving the quality and efficiency of production.

Comparison of jig & fixture and labor

In addition, through the above-mentioned applications, we can also improve labor productivity and reduce production costs to a certain extent. Because if you only rely on manual operations to perform related operations, the auxiliary time of the work will take up a large part of the total time, and because it is manual operation, it is easy to cause excessive errors or even operational errors during the operation. Phenomenon. From this point of view, the application design and in-depth analysis of jig & fixture in production practice is very necessary.

The basic principle of jig & fixture design

Generally speaking, different processes involved in different workpieces have different requirements when applied to machining. Therefore, before using jig & fixture to process machinery, it is necessary to accurately find the position of the workpiece on the machine tool and the tool to implement high-standard machining.

When performing machining, the focus should be placed on the workpiece clamping task to be completed. In the process of processing, the fixture should be regarded as an auxiliary tool in order to smoothly complete the mechanical processing. From the aspect of the machining system, the important position occupied by the jig & fixture has also been importantly reflected.

When positioning the workpiece, the staff needs to measure high-precision data, because the final accuracy of the workpiece will directly affect the quality of machining, so the high-precision requirements of the management personnel of the machinery enterprise for machining become understandable. At the same time, there are three relative position situations when positioning the workpiece. First, the positioning of the workpiece is relative to the fixture; second, the positioning of the workpiece is relative to the machine; and third, the positioning of the fixture is relative to the machine. Most of the time, the positioning of the workpiece is more accurate than the positioning of the machine tool.

jig & fixture positioning problem

When jig & fixtures are used in machining, it is necessary to clarify the basic positioning problems, and to deal with the positioning problems in place, then the accuracy of machining will be more accurate, and the quality of machining will also be improved invisibly.

When machining the workpiece, it is necessary to ensure the quality and productivity of the product, and the fixture is the key to solving this problem. When using jig & fixtures to carry out mechanical processing, it is necessary to understand the basic principles of fixture design in order to smoothly complete the mechanical processing. It is necessary to clarify the positioning reference category of machining in order to reflect the rationality of the workpiece.

It is necessary to be clear about the positioning of the jig & fixtures, so as to make different positionings for different workpieces, so that the quality of the workpieces is more guaranteed. A thorough understanding of every problem involved in mechanical processing is conducive to more freely processing workpieces, and it can also improve the work efficiency of workers. This is of great benefit to reducing the production cost of the enterprise and improving the production efficiency.

In short, when machining a workpiece, no matter what clamping tool or positioning method is used, the prerequisites must ensure the stability and reliability of the produced product. Only by doing this can the jig & fixture be machined. Only with the value of China can the enterprise have a broader development prospect.

评论

发表评论