Automatic machinery parts machinery development trend

The application range of automated machinery is also relatively wide, and automated machinery is not a whole. It also requires a lot of accessories to form a complete machine. Automated machinery comprises five accessories, so can mechanical automation always exist and update iteratively? The following is a detailed introduction to the development and trend of automation machinery parts machinery and automation, hoping to help everyone.

1. Introduction to automatic machinery parts

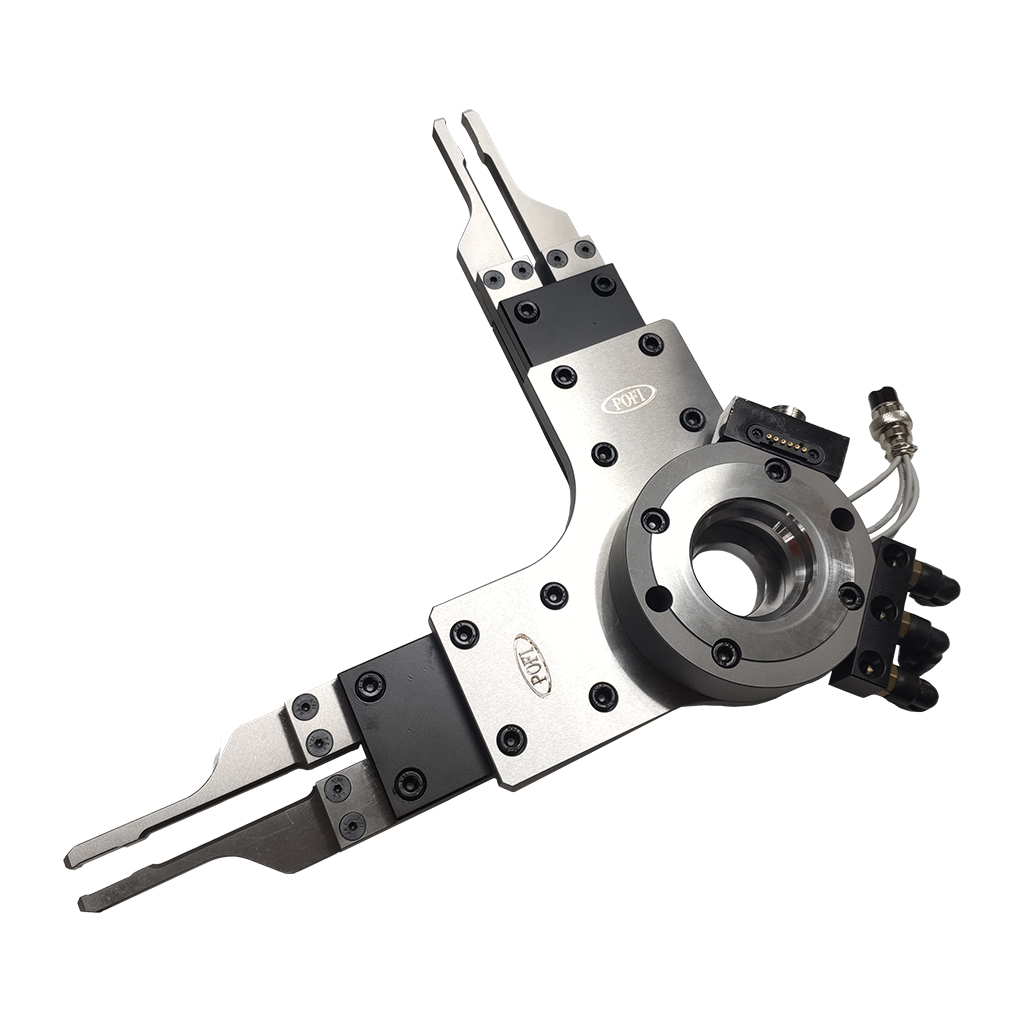

Automatic mechanical parts are mainly transmission parts, drive controllers, sensors, fixtures, electronic components, pneumatic cylinders, etc.

1. Transmission parts nut rotary ball screw, guide rail, slider, nut seat, support seat, coupling, mainly used to realize the transmission function. The rotary R&D and production of the nut, the core component of the transmission, will replace the working method of the ball screw nut of the transmission, effectively speeding up the R&D and development of mechanical automation.

2. Components, drive programming, and control switches of various components of the drive controller;

3. The action and working method of the final realization of the automation of the fixture;

4. Electronic components control panel and positioning switch, circuit board;

5. The pneumatic cylinder mainly assists the fixture in absorbing, picking up, and putting down.

Since the Industrial Revolution, the machine manufacturing industry, based initially on manual technology, has gradually been transformed into machine technology. The rapid development of science and technology has entered the development stage of modern industry. In today's society, the realization of mechanical automation has undoubtedly pushed machinery production into a new field. Mechanical automation is the realization of automatic control. The control system dramatically increases the production volume while reducing the employees' labor and improving labor efficiency and production quality. Today's machinery manufacturing is inseparable from the automation system.

The major of machinery manufacturing automation covers a wide range of fields. It produces products required by various industries in the broad machinery manufacturing field and impacts design and manufacturing, technology development, and even business sales. This determines the importance of the machinery manufacturing industry, which has a vast demand and scale, so it needs a vast team of professionals.

Machinery manufacturing is one of the most important productive sectors in the national economy. In the production process of machinery manufacturing, natural resources and raw materials are mainly processed or assembled. This is an industry with relatively high wages, but the work is also relatively complex, and it requires specific physical fitness and skills for those engaged in this industry. With the excellent development of the machinery manufacturing industry, the talent market will have a greater demand for mechanical talents. To cooperate with advanced technologies such as mechanical automation, CNC talents with development ability will become the competition target among enterprises. The supply and demand ratio for mechanical design, manufacturing, and processing professionals has also been high in recent years.

评论

发表评论